Introduction

Silicone leather, known for its durability and eco-friendliness, is becoming a popular synthetic leather alternative. Made from silicone, it’s hypoallergenic, water-resistant, and withstands extreme conditions. This cruelty-free material mimics natural leather in texture and appearance, suitable for fashion, upholstery, and automotive uses.

The production of silicone leather involves applying a surface agent on release paper, followed by baking to set this layer. Subsequent layers of leather glue and a microfiber cloth addition provide strength and a leather-like feel. The final bake solidifies the material, resulting in high-quality silicone leather.

This innovative process highlights the evolving landscape of material technology, combining aesthetics, functionality, and environmental consciousness. Silicone leather’s growing popularity marks it as a sustainable choice in various industries.

Step-by-Step Guide

Creating a sample of silicone leather involves a series of meticulous steps, each critical to achieving the final product’s quality and characteristics.

This guide provides a detailed walkthrough of the entire process, emphasizing the importance of each stage in producing high-quality silicone leather.

Applying Surface Agent on Release Paper: The first step in silicone leather production is the application of a surface agent onto release paper. This process involves evenly rolling a specially formulated surface agent across the surface of the release paper. The precision in this step is crucial as it determines the texture and initial layer of the silicone leather. The surface agent acts as a foundation, ensuring that subsequent layers adhere properly and contribute to the final product’s overall quality and durability.

Baking at 130 Degrees Celsius for 3-5 Minutes: After the surface agent is applied, the release paper is subjected to a baking process at a temperature of 130 degrees Celsius for 3 to 5 minutes. This baking step is essential for setting the surface agent. The specific temperature and time duration are carefully calibrated to ensure that the agent cures properly without over-drying or under-setting. This process solidifies the agent, forming a stable base for the next layers.

Applying Leather Glue on Release Paper: Following the initial baking, the next step involves applying a layer of leather glue onto the prepared release paper. This is done by evenly rolling out the leather glue, ensuring consistent coverage. The leather glue plays a pivotal role in the durability and texture of the silicone leather. It provides the necessary bonding strength for the layers and adds to the material’s overall toughness and flexibility.

Second Baking at 130 Degrees Celsius for 3-5 Minutes: The application of leather glue is followed by another baking process, similar to the first one. This second baking at 130 degrees Celsius for another 3 to 5 minutes is necessary to solidify the leather glue. This step ensures that the glue is properly set and integrated with the surface agent, further enhancing the material’s structural integrity.

Reapplying Leather Glue on the Same Area: To reinforce the strength and quality of the material, the leather glue is reapplied over the same area. This process involves another careful application of the glue, ensuring that it covers the previously treated surface uniformly. The addition of this extra layer of glue not only adds to the material’s resilience but also contributes to its aesthetic texture, making it more similar to natural leather.

Attaching the Microfiber Cloth Without Further Baking: Once the second layer of glue is applied, a microfiber cloth is attached to it without additional baking. This step is crucial for the tactile feel and appearance of the final product. The microfiber cloth is pressed firmly onto the glue-coated surface, ensuring proper adhesion. This cloth adds a layer of softness and texture, mimicking the feel of genuine leather.

Final Baking at 130 Degrees Celsius for 3-5 Minutes: The final step in the process involves another round of baking. This last bake at 130 degrees Celsius for 3 to 5 minutes is critical for ensuring the complete bonding of all layers – the surface agent, the leather glue, and the microfiber cloth. This process solidifies the composite material into a cohesive unit, finalizing the structural and textural properties of the silicone leather.

Removing the Release Paper: The last stage in the creation of the silicone leather sample is the removal of the release paper. This step must be done with care to preserve the integrity of the silicone leather. Gently peeling away the release paper reveals the final texture and quality of the silicone leather, showcasing its smoothness, flexibility, and resilience.

Each of these steps, from the initial application of the surface agent to the final removal of the release paper, is crucial in defining the quality, durability, and aesthetic appeal of the silicone leather.

The meticulousness and precision involved in the process ensure that the final product not only resembles natural leather in look and feel but also surpasses it in terms of durability and maintenance.

The entire process exemplifies the innovation and technological advancement in material production, offering a sustainable and high-quality alternative to traditional leather products.

Discover the art of crafting high-quality silicone leather in our concise video demonstration. This visual journey takes you through each critical step of the production process, highlighting the precision and expertise involved. From applying the surface agent to the final stages of baking and finishing, the video showcases the meticulous techniques that ensure silicone leather’s durability and aesthetic appeal.

We encourage you to watch this demonstration for a clearer understanding of the intricate process behind this innovative material. It’s an enlightening glimpse into the craftsmanship that makes silicone leather a top choice for various applications.

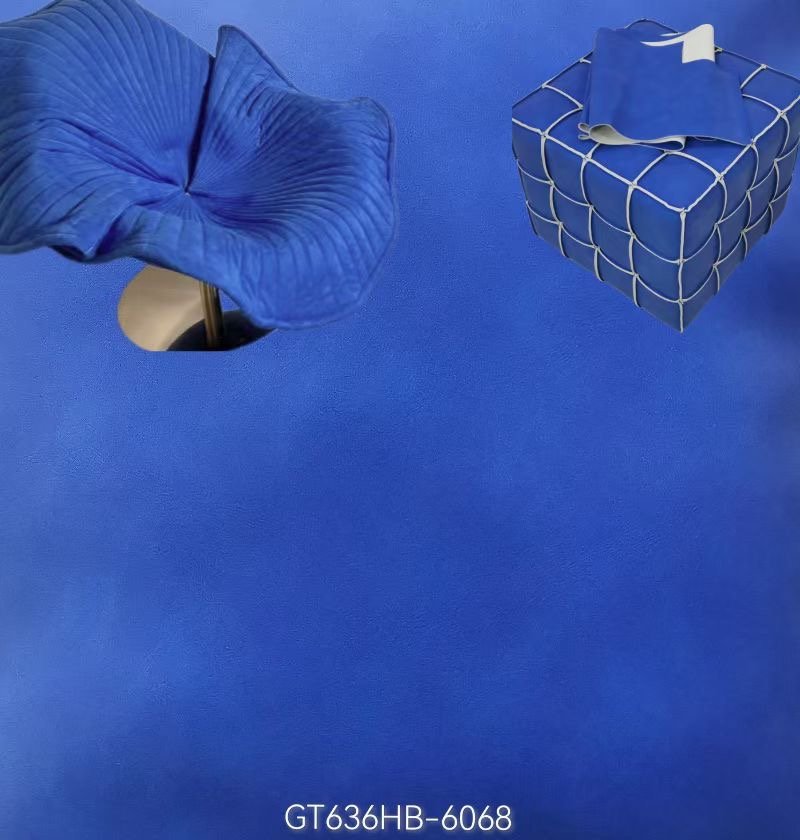

The final silicone leather product stands out for its exceptional properties. Its surface boasts a remarkable smoothness, giving it a luxurious feel akin to high-quality natural leather. Notably resistant to stains and scratches, this material maintains its pristine appearance even under rigorous use, making it ideal for high-traffic areas and everyday items.

Additionally, silicone leather is skin-friendly, ensuring comfort and safety for all users. These attributes make it highly versatile, suitable for a wide range of applications from upscale furniture and automotive interiors to fashionable accessories and clothing. Its durability, combined with aesthetic appeal, positions silicone leather as a preferred choice in various industries seeking both functionality and style.

In conclusion, the process of creating silicone leather is a testament to the fusion of innovative technology and meticulous craftsmanship. Each step, from applying the surface agent to the final baking, is crucial in ensuring the high quality of the final product.

Silicone leather emerges as an exceptional material, characterized by its smoothness, durability, and versatility. These properties make it an ideal choice for a variety of applications, offering both aesthetic appeal and practical functionality.

Whether used in furniture, fashion, or automotive interiors, silicone leather stands out for its ability to enhance product quality while meeting diverse industry needs.

We invite you to delve deeper into the world of silicone leather and discover the myriad of possibilities it offers.

If you’re intrigued by the durability, aesthetic appeal, and versatility of silicone leather, we encourage you to explore our range of products. For any inquiries or to learn more about how silicone leather can elevate your projects, please don’t hesitate to reach out to us.

Our team is ready to provide you with further information and assist you in making the most of this innovative material.

Step into the world of artificial leather with our extensive selection, featuring PU, EPU, PVC, Semi PU, Silicone Leather, Microfiber Leather, Saddle Leather, and Eco Leather. Designed to suit diverse preferences and applications, our collection promises quality and variety. Find your ideal artificial leather with us today.